Our Specialties

OUR SPECIALTIES

TYPES OF SHEENS

- MATTE

- SATIN

- SEMI-GLOSS

- GLOSS

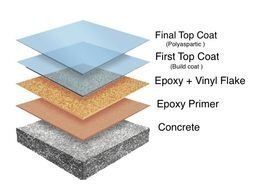

EPOXY

OUR PROCESS

- Step 1: Grind existing surface with concrete grinder

- Step 2: Fill cracks with Epoxy filler and prime the surface

- Step 3: Apply layer of Epoxy with broadcast flake

- Step 4: Apply the first coat (build coat)

- Step 5: The last step and the most important step, we apply polyaspartic top coat

BENEFITS OF EPOXY FLOOR

- UV resistant: protects against deterioration and discoloration

- Hot tire resistant: curbs delamination caused by hot tires

- Chemical resistant: resists chemical spills and cleaners

- Waterproofing: protects surfaces and underlying areas from water intrusion

- Anti-microbial: protects against bacterial and fungal growth

POLISHED CONCRETE

Polished Concrete is a multi step process that exposes aggregate from the cap or cream of the concrete. This process is done mechanically with a Concrete Grinder.

OUR PROCESS

Step 1: Diamond grind surface to a scratch free finish

Step 2: Add color if desired

Step 3: Let densify/harden

Step 4: Apply Sealant

UNDERLAYMENT

OUR PROCESS

- Step 1: Coarse diamond grind surface

- Step 2: Prime

- Step 3: Self-level underlayment

BENEFITS OF UNDERLAYMENT

- Sound Reduction or Dampens Noise.

- Moisture Protection – Blocking Harmful Damage To Your Floor.

- Compression Resistance.

- Smooths Subfloor Imperfections.

- Insulating Value.

Contact Us

425-766-5435 : Tracy Miller

425-516-5542 : Sean Hansen

tracy@premieroverlay.com

sean@premieroverlay.com

Location:

PO Box 307 Fall City Washington

98024

Business Hours

- Mon - Sun

- Open 24 Hours

License #PREMIO*819QM

© 2025

Premier Overlay